Solar Panels Maintenance Guide

Having a good solar panel system is only half the job. The other half is what makes the difference in the long run: preventive maintenance.

Solar panels may be considered low-maintenance, but the reality is that installations that do not receive regular attention lose efficiency faster than you might expect. In the long run, that means lower performance and more repairs, two factors that no company is interested in.

That is why it is key to have a maintenance strategy that not only ensures that the panels operate at their maximum potential, but also extends their useful life, avoiding any major breakdowns.

In this guide we tell you everything you need to know to design and implement an effective maintenance program for solar panels, from routine maintenance of the solar panels to the cleaning to periodic inspections.

Preventive maintenance, when done right, is an investment that always pays off.

It’s not just a matter of dusting or checking for cracks, it’s about making sure the entire installation is optimized and working at its best.

Recommended frequency

The most common mistake is to put maintenance on the back burner or, worse, to assume that the plates maintain themselves.

Solar panels, although robust, are constantly exposed to the elements, and this affects their performance more than many realize. A dirty or deteriorated panel can lose up to 30% efficiency.

So, if you want to get the most out of your solar investment, it is vital to schedule regular preventive maintenance.

Depending on location

The geographic location of the facility is key to defining the frequency.

An installation in a rural area with little pollution is not the same as one near a factory or in coastal areas, where sea salt can accumulate quickly.

Here are some factors to consider:

- Industrial or urban areas: In these areas, pollution and dust tend to adhere to the solar panels. More frequent cleaning is recommended, approximately every 4-6 months.

- Dry or desert areas: Dust and soil can drastically reduce the production of the plates. Make sure to remove the dirt every 2-3 months for maximize your investment.

- Coastal areas: Salty air is the number one enemy of solar panels. If your installation is near the sea, it is advisable to clean them every 2-3 months. to prevent corrosion and salt accumulation.

Depending on the season

In addition to geographical factors, seasonal conditions also affect maintenance planning.

During the spring and summer, dust and debris tends to accumulate more quickly due to the lack of rainfall.

On the other hand, in winter, depending on the region, you may need more specific cleaning to remove snow or ice.

A good approach is to schedule general inspections every 6 months, with intermediate cleanings depending on the season and specific environmental conditions. In case of doubt, you can always resort to an on-site evaluation, which will help you adjust the frequency according to the actual condition of the panels.

Cleaning methods

Solar panel cleaning is one of the most critical tasks in a preventive maintenance program.

It not only ensures that the plates operate at maximum capacity. It also avoids long-term problems resulting from the accumulation of residues, such as the notorious “hot spots”, which can damage the system.

However, cleaning solar panels is not as simple as wiping them with a cloth.

A bad procedure or the use of inappropriate products can cause more harm than good.

Tools and products

One of the biggest challenges when cleaning solar panels is to use tools that remove dirt without damaging the glass of the panels.

The types of tools that exist are:

Manual brushes

The simplest and cheapest. They work as a broom, rubbing over the plates manually. They are ideal to start cleaning small installations, but they are very tiring.

We recommend automated brushes such as the P1 pole. They are more expensive, but they are less tiring and allow more panels to be cleaned per day.

Pressurized water

They clean the plates with a pressurized water gun. It is less tiring than a manual brush, but it is also more expensive. They use tons of water, and on top of that they can damage the plates if you have too much pressure. We do not recommend it.

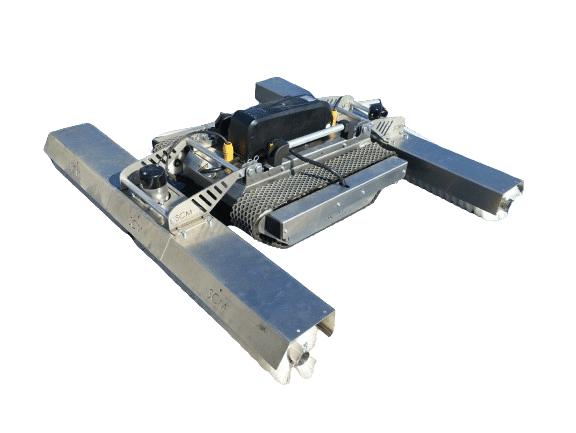

Remote control robots

Similar to one of those automatic vacuum cleaners that clean your house by themselves. But in this case you control them with a Radio-Control remote control.

They are ideal for low-slope solar roofs in warehouses and industrial areas.

Look for 2 long brushes and a light weight: you will have to carry it and put it on many roofs.

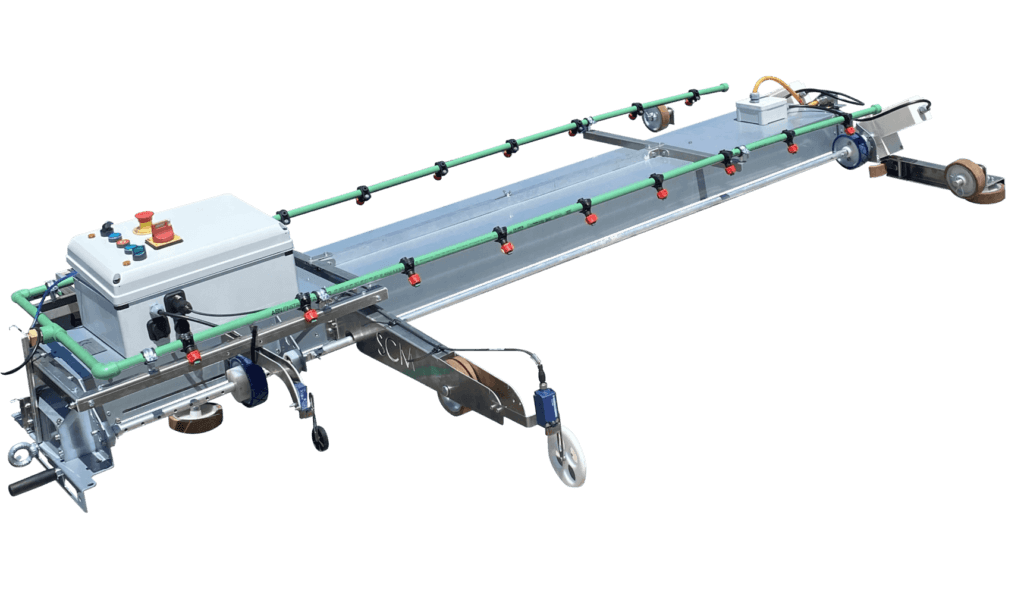

Automatic robots

Suitable for solar parks. They are basically a brush with wheels. They come and go by themselves along the entire row of solar panels.

In most cases, you will only need a single robot that you can switch from one row to another or take it to another floor, such as the S2 model.

But you can customize them as much as you want: They can be cleaned manually like the K2 model, or we can make a fully automated fleet on demand.

Above all, make sure that the brush is running at a constant speed. counter direction. And if it has 2 brushes instead of 1, all the better.

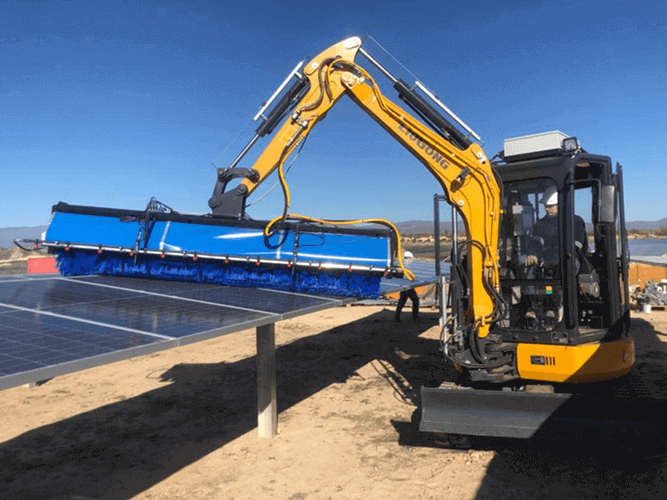

Hydraulic arms

They are anchored to a vehicle such as a tractor or a backhoe, and they clean the plates as you drive.

They are the most expensive tools, but they are also the fastest and require the fewest people: a single person can clean a large solar farm in a single day.

Look for arms that do not support weight on the panels, to avoid breaking them. And if they are automatic like the

D2 model better, so that the driver only has to drive without worrying about the arm.

Dry vs. wet

Both have their advantages and disadvantages, and your choice will depend on both the environmental conditions and the equipment available.

- Dry cleaning: Ideal for areas with low levels of soiling or where water use is limited. Microfiber brushes or specialized equipment are used to remove dust without scratching the panel surface.

This type of cleaning is fast and suitable for frequent cleanings in areas with light dust. - Wet cleaning: It is the most common and effective in areas with heavy soiling, such as dense dust, pollen or industrial residues.

Distilled water or non-abrasive additives should be used. Avoid tap water, as minerals may leave residues.

It is especially useful for removing stubborn stains or sticky patches that cannot be removed. are removed by dry cleaning.

How to clean step by step

Once the right method and tools have been chosen, it’s time to get down to work. Here is a standard procedure that guarantees safe and effective cleaning:

- Preparation: Before starting the cleaning, make sure that the cleaning tool is compatible with your installations.

The antennas, the clamps, the inclination of the panels, the condition of the floor, the height of the plates… There are many things that can make maintenance difficult.

If you are not sure, ask us and we will take a look at it for free, without obligation! - Panel condition assessment: Perform a quick inspection to identify particularly dirty or damaged areas. This will help you prioritize areas where concentrate the cleaning effort.

- Removing surface dust: If you opt for dry cleaning, start with a soft bristle brush to remove loose dirt and dust. If the dirt is more embedded, go to the next step.

- Distilled water application: For wet cleaning, use a low pressure water system or spray to spray the panels.

Be sure to cover the entire surface evenly. If there are stubborn stains, use a brush with demineralized water to scrub gently. - Natural drying: Once the surface is clean, allow the panels to dry naturally.natural way. Avoid using cloths or rags to dry them, as this may leave fibers or residues that affect performance.

Tip: Never clean the panels when they are very hot. Especially at midday, when they are exposed to the sun for hours.

Thermal shock with cold water can damage the plates.

Perform cleanings early in the morning or at the end of the day, when temperatures are cooler and more stable.

How to identify problems

Preventive maintenance is not limited to cleaning the solar panels.

During each overhaul, it is crucial to perform a visual and technical inspection that allows you to detect possible faults before they become serious failures.

This not only saves you time and money on costly repairs, but ensures that the system operates at peak efficiency at all times.

Visual inspection: What to look for

A trained operator can detect problems at a glance.

Some of the most common problems you should be aware of are:

- Micro-cracks in the panels: These small cracks, almost imperceptible to the naked eye, can cause a significant loss of efficiency over time.

Although not immediately affected, with constant heat and cold, these cracks can grow and cause irreparable damage. - Hot spots: These are formed when a cell inside the panel is damaged by the overheats due to clogging or malfunction.

Hot spots not only reduce panel efficiency, but can permanently damage the affected cells.

Use a thermal imaging camera or look for discolorations on the surface of the panel that are may be indicative of a hot spot. - Shadows from nearby objects: Although not a technical problem in the panel, the presence of shadows from trees, antennas or even nearby buildings can be a problem.

If you detect shadows in critical areas, adjustments to the location or angle of the plates will be necessary. - Accumulation of non-cleanable residues: bird droppings, tree sap, industrial waste… They are very difficult to remove, and need more specific cleaning solutions to avoid long-term damage.

If you have this problem, ask us and we will take a look at it for free, without obligation!

Use thermal cameras

One of the most useful tools for advanced preventive maintenance is the thermal camera.

They allow to detect if any cell is operating at a different temperature from the rest, which indicates problems such as:

- Faulty or inactive cells: If a cell is not working properly, its temperature will be higher than that of the others, due to heat accumulation.

Since it does not effectively generate electricity, it absorbs solar energy in the form of heat. - Problems in the wiring or connections: A loose wire or connection can also generate excessive heat in certain areas of the installation.

Thermal cameras find these problems quickly, so you don’t have to disassemble the entire system to find the fault.

Monitor efficiency

More and more solar installations have remote monitoring systems that allow you to track the performance of the panels in real time. These systems alert you if there are sudden drops in efficiency or if a specific panel stops working properly.

This way, you can intervene immediately before the problem affects the overall performance of the installation.

Remote monitoring not only improves responsiveness to problems, but also provides valuable data that allows the preventive maintenance program to be adjusted according to the actual behavior of the panels.

Minor breakdowns, before they become major ones

One of the greatest benefits of a good preventive maintenance program is the ability to identify and resolve minor breakdowns before they become major problems.

In many cases, these small faults are not detected in time, which can lead to costly repairs or even replacement of key components.

Common repairs

Most of the minor failures in solar panel systems are related to the natural wear and tear of some components or problems that arise due t o lack of proper maintenance. Below, we list some of the most frequent ones and how to solve them:

- Loose or corroded connections: The electrical connections in a solar system are exposed to the elements, which means that, over time, they may rust or loosen.

It is important to check these connections and adjust or replace them if necessary. A simple tightening of the connectors can prevent power outages or inefficient power transmission. - Inverter wear and tear: Over time, inverters can suffer from wear and tear, or even fail completely.

Replacing an inverter is a big expense, so it is better to perform minor adjustments or cleaning to extend its life.

During regular inspection, check the inverters for dust accumulation or cooling fan problems. - Microcracks in the panels: If during the visual inspection you detect small cracks in the panels, it is essential to perform a more in-depth technical evaluation. Although not all microcracks require immediate intervention, some may expand over time and affect overall performance.

In some cases , temporary repairs can be performed to prolong the life of the life of the panel until it can be replaced.

Periodic changes

Change minor components during preventive maintenance to avoid major breakdowns.

From small connectors to fuses and cables, periodic replacements ensure that the system continues to function optimally.

In addition, it is always advisable to have on hand an inventory of key components, such as inverters, fuses and other system elements. This allows quick repairs to be made without waiting for long lead times or making emergency.

Be sure to choose suppliers with a stock of spare parts and good technical service.

Document and record maintenance activities

You must keep a detailed record of the interventions.

This not only helps you to have a clear history of all actions performed, but is also key to anticipate future breakdowns or identify wear patterns.

Some items to include in the maintenance documentation are:

- Date and type of maintenance performed.

- Visual and technical inspections performed.

- Components replaced or repaired.

- Observations on panel performance before and after maintenance.

Documentation is particularly useful for large installations, where there may be multiple panels and components.

Tips according to the type of installation

Cleaning and maintaining a large-scale solar farm is not the same as cleaning and maintaining a commercial or residential installation.

Each type of installation poses different challenges and requires customized solutions to maximize the efficiency and durability of the panels..

Large-scale solar farms

Solar farms, due to their size, are usually more complicated to maintain.

But they are also the facilities where preventive maintenance has the greatest impact on cost optimization and energy production. Some key tips for this type of installation:

- Plan for maintenance: In a large solar farm, it is often impractical to clean all the panels at once.

It is advisable to divide the installation into phases, planning the cleaning of different sections throughout the year. This allows constant maintenance without stopping the overall production. - Use specialized equipment: Automated cleaning equipment allows you to clean faster and with fewer personnel.

The ideal is to use robots like the S2 model or hydraulic arms like the D2 model. After all, you can use the tractor for other maintenance tasks. - Periodic inspections: Given the size of these installations, it is recommended that use advanced technologies, such as drones with thermal imaging cameras, to identify hot spots or defective cells without having to check each panel manually.

Commercial facilities

They are often found on sloping roofs or in areas with limited access, requiring a more specialized approach to cleaning and safety.

Some key recommendations for this type of installation are:

- Secure access: It is essential to ensure that maintenance crews use the following safety systems and are trained in working at heights. Telescopic hoses and specialized brushes for sloped roofs, such as the P1 pole, can greatly facilitate the task.

- Monitor performance: Commercial installations are often connected to remote monitoring systems.

This makes it easy to detect any problems in real time. This allows the maintenance team to fix it before performance is affected. - Scheduled cleaning: It is important to plan cleaning and maintenance outside of peak building activity hours.

This ensures that there are no interruptions in the use of the power generated and minimizes disruption to occupants.

Installations in extreme climatic conditions

In regions with extreme weather conditions, such as areas with high temperatures, hail, or frequent snowfall, the maintenance approach must be adapted to these conditions.

Some specific tips are:

- Hail protection: In areas prone to hail storms, it is advisable to install additional protection, such as temporary covers or protective screens, to prevent damage during storms.

In addition, after a storm, it is crucial to perform a detailed inspection to detect possible cracks or damage. - Snow removal: It is important to remove the accumulated snow on the panels, since that this can block sunlight and even split the plates due to the weight.

Snow should be removed with appropriate tools, such as specialized brushes or hot air systems, to avoid damaging the plates.

If you have this problem, ask us and we will take a look at it for free, without obligation! - High temperatures: It is essential to carry out periodic inspections in order to identify problems related to overheating, such as hot spots.

In addition, if you pour cold water on the plates when it is very hot, they may suffer thermal shock and be damaged.

Adjusts maintenance to ensure adequate ventilation of the panels.

Conclusion

If you want to stop losing money, or provide services to other companies, write to us and we will help you for free.

We offer complete training, 24/7 assistance, and spare parts at all times. available. In addition, we have an international network of distributors to ensure that you always have the support you need.