Advantages of the electronic regulation of photovoltaic parks cleaning

- Photovoltaic parks cleaning

- 25/01/2023

SUMMARY

At present, we live in a world of constant evolution and there are great discoveries that have allowed us to develop more and more accurate machines. Therefore, in this article a brief comparison will be made and we will discover the great advantages of electronic regulation in the cleaning arms of photovoltaic parks.

We see this throughout the industry where it has gone from purely mechanical systems as it was in the industrial revolution S. XVIII to have a great variety of electrical-electronic components in our days.

1. INTRODUCTION

ELECTRONIC REGULATION

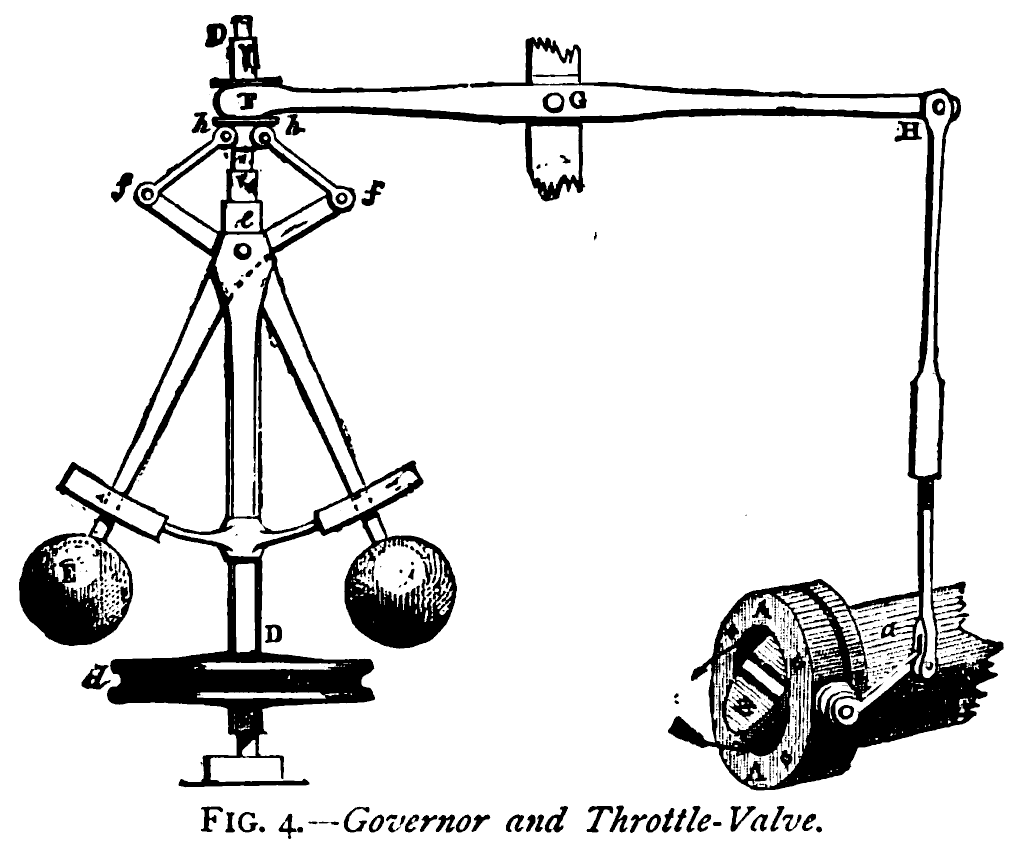

According to this definition we can find throughout history a large number of examples of automaton. Among them animated statues that would have been built in the temple of Daedalus. (Ancient Greece). In the eighteenth century Jacques de Vaucanson built a series of works among which are “THE FLAUTIST”, a figure who is able to play a wide repertoire with drum and flute; “THE DRUMMER” and his most famous work “DUCK WITH DIGESTIVE SYSTEM”, which was a mechanical duck capable of flapping wings, diving, swimming, swallowing grain, and even excreting a dropping-like product. Focusing on industrial automation, we can say that it begins with the invention of the centrifugal regulator by James Watt (1778), WHICH CONSISTED OF A MECHANISM THAT KEPT THE OUTPUT SPEED OF THE SYSTEM CONSTANT DESPITE LOAD FLUCTUATIONS. Maintenance of renewable energy facilities. Regulator by Watt R. Routledge – image from “Discoveries & Inventions of the Nineteenth Century” By R. Routledge, 13th edition, published 1900.

Regulator de Watt [R. Routledge – Image from “Discoveries & Inventions of the Nineteenth Century” by R. Routledge, 13th edition, published 1900.]

2. BASIC CONCEPTS

AUTOMATION

The automation of a machine consists of adding a technological device that is responsible for controlling its operation. Therefore, the final system where the device has been added, generically called automatism, is capable of reacting to the different circumstances that arise by modifying its operation (control action) depending on what it has been designed for.

AN AUTOMATED SOLAR CLEANING SYSTEM IS COMPOSED OF:

- A machine or process to control.

- A control unit in charge of executing the necessary actions

- Set of controllers or interface elements between the machine and the control:

Composed of sensors responsible for collecting the information used by the control unit and actuators that receive the orders of the system, transforming them into physical changes of the system through the contribution of energy.

According to the nature of the energy used for the control of the automation, we can speak of mechanical, pneumatic, hydraulic, electrical and electronic automation. IN ADDITION TO EXISTING MIXED TECHNIQUES THAT ARE COMBINATIONS OF THOSE CITED. COMMENTING BELOW THOSE DISCUSSED IN THIS ARTICLE:

MECHANICAL AUTOMATION

They are composed of They are composed of: -Wheels for the TRANSMISSION OF MOVEMENT of connecting rod-crank - Pinion - rack, etc TRANSFORM r rectilinear movement in circular, vice versa -Cams, springs and levers to obtain CONTROLLED ROUTES. Some examples of mechanical automatisms in industry are: mechanical _relojes, internal combustion engines and all the machinery that was part of the industrial revolution.

ELECTRONIC AUTOMATION

Digital systems have been the basis of this great advance, on one hand, with computers and on the other by programmable automats. The programmable automata, PLC (programmable logic control) is an electronic equipment that thanks to a series of inputs (sensors) and outputs (actuators) can control sequential processes in real time in industrial applications of different kinds. Main virtues: - Reliability and improvement of process control - Allows rapid changes in maneuvers and processes - Reduces the volume of automation - Increases the degree of safety of controlled facilities - Continuous interaction with the operator (information feedback).

3. AUTOMATION OF CLEANING ARM IN PHOTOVOLTAIC PARKS.

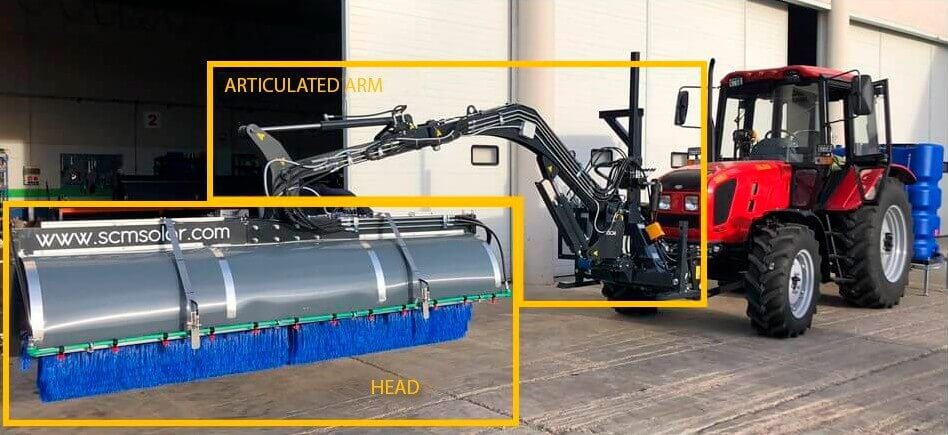

AN ARM FOR CLEANING PHOTOVOLTAIC PARKS IS A DEVICE GENERALLY FORMED BY THE FOLLOWING COMPONENTS:

1. head

Formed by a brush and its structural support; The brush is the fundamental part since it is the one that performs the cleaning and is in contact with the panel.

2. ARTICULATED ARM

It is a metal structure articulated in several of its points, which through a series of mechanical elements allows its movement, to perform these movements pistons and hydraulic motors are used.

- Anchor the arm to the vehicle and attach the hydraulic connections of the arm to the hydraulic intakes of the tractor.

- Position the brush parallel to the line of photovoltaic panels; This action is usually performed with a wireless control that allows you to move your arm by means of a joystick.

- Once the parallel brush is placed, the cleaning will be activated in automatic.

MECHANICAL REGULATION:

In this case the regulation is done by raising and lowering the arm by means of a shock absorber according to the pressure exerted on the line of panels.

In this case the movement of the head is free. The regulation depends mainly on the shock absorber being properly calibrated.

ELECTRONIC REGULATION

The regulation is done by a series of sensors which continuously measure the distance from the head to the row of panels, this measurement is sent to the PLC, which will exercise the necessary correction actions on the pistons, moving the head or raising and lowering the arm, to keep the head parallel to the panel line at all times.

DIFFERENCES IN REGULATORY SYSTEMS:

AN AUTOMATED SOLAR CLEANING SYSTEM IS COMPOSED OF:

1.IN MECHANICAL REGULATION THE BRUSH IS CONTINUOUSLY EXERTING WEIGHT ON THE PANELS.

However, in the case of electronic regulation there is no weight as such, since the only thing that will touch the panels are the strands of the brush, not the brush as a whole. So the loads exerted on the panels are lower in the electronic regulation obtaining greater care in these.Electronic regulation obtaining greater care in these. In the case of panels without aluminum frame (dual glass) the permissible loads are even lower so the electronic regulation has this great advantage.

2. The electronic regulation allows to vary the distance to the line of plates along the route.

This makes it possible to avoid obstacles along the line of panels, such as antennas, protrusions of the structure, etc.; Elements increasingly common in plants. In mechanical regulation it does not have the ability to vary the distance, therefore, it is necessary to stop cleaning, so that the operator takes control and avoids it. However, if the operator does not notice the obstacle, he will probably damage the element in question, and possibly damage the arm.3. THE ELECTRONIC REGULATION HAS THE CAPACITY FOR CONTINUOUS IMPROVEMENTS AT THE PROGRAMMING LEVEL, R + D + I, AS WELL AS ADDING NEW FUNCTIONALITIES, SENSORS OR ACTUATORS;

Which allows an evolutionary up-grade. Unlike mechanical regulation, the arm is limited to its design at the time of purchase, since introducing new functions involves a redesign of it.Hydraulic arm Automatic robot Manual robot Customization

We do not intend to sell a type of product at all costs. Our mission is to offer you the best product based on the different types of problems to solve. We propose the best solution to each client’s problem, whether or not it is done with our equipment.